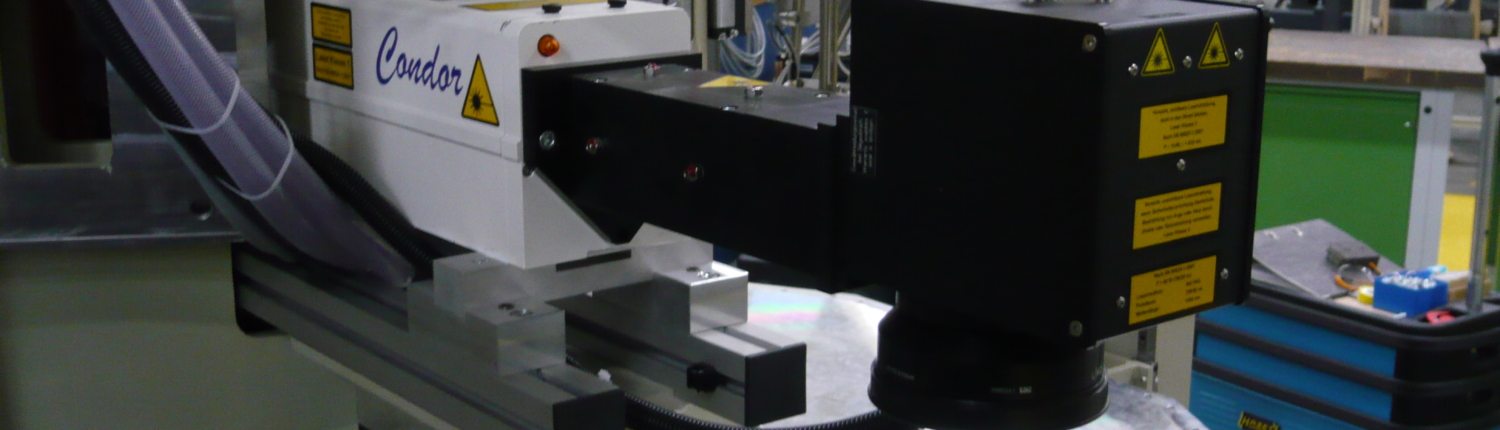

Maximum safety in production: mix-up detection with laser precision

Material mix-ups? Not with us.

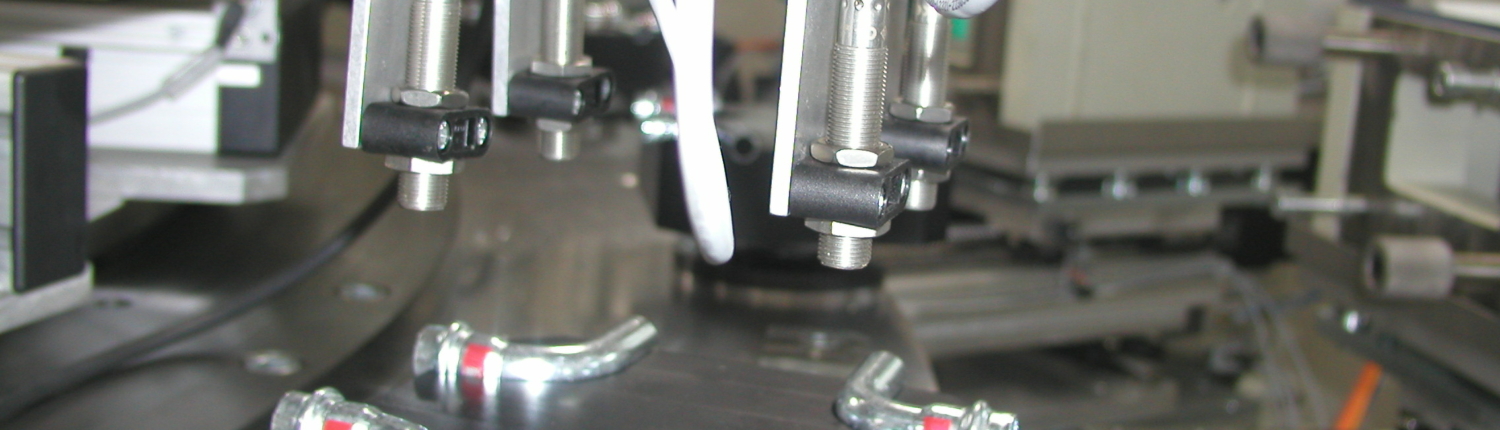

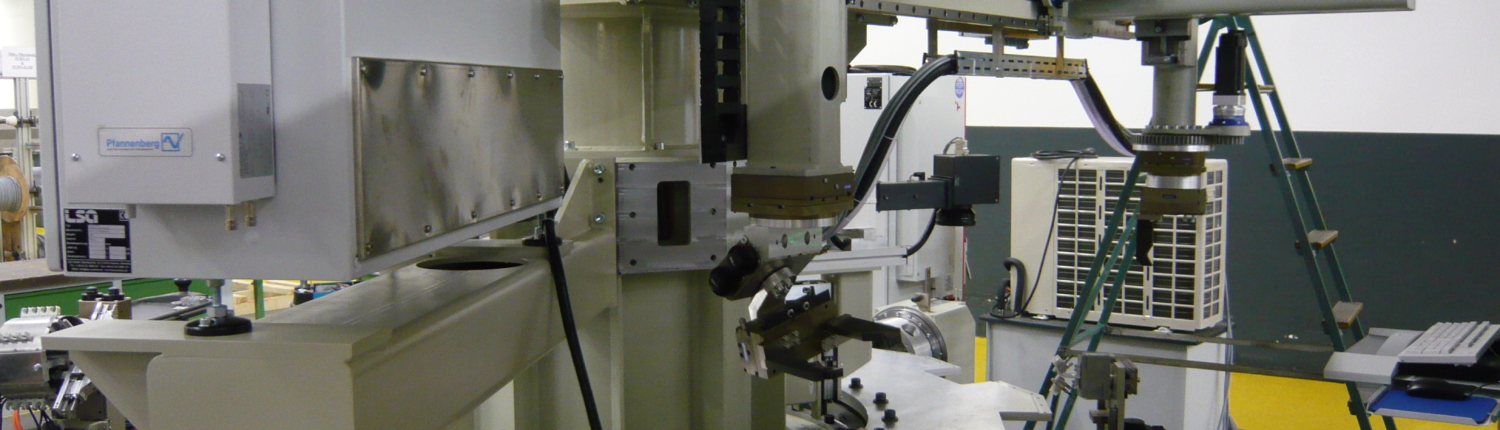

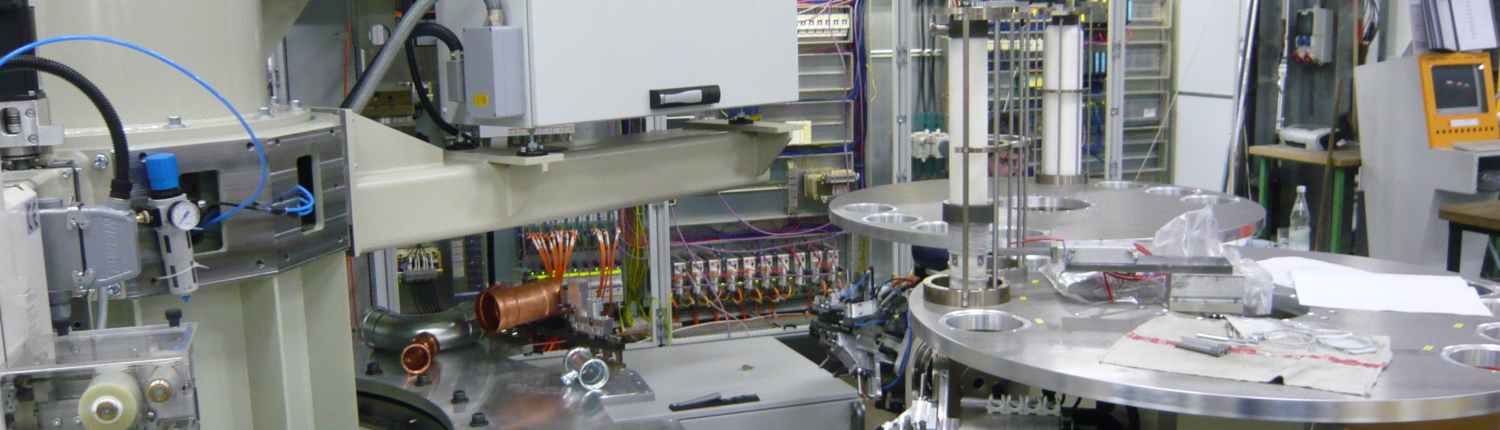

Our innovative in-line mix-up inspection based on laser-induced breakdown spectrometry (LIBS) brings maximum precision and reliability directly to your production line. Detect materials in real time – quickly, reliably and under the toughest conditions.

Why our laser mix-up test?

🔹 Precision in real time

Even in complex industrial environments, our system reliably identifies a wide variety of materials – directly in your ongoing production.

🔹 Lightning-fast analysis

Thanks to the latest algorithms and powerful hardware, you can detect material mix-ups in seconds and react immediately.

🔹 Versatile

Whether in the metal industry, chemicals, manufacturing, recycling or mining – our solution adapts flexibly to your requirements.

🔹 Built for industry

Robust hardware guarantees reliable performance, even under extreme conditions – durable, efficient and low-maintenance.

Your advantages at a glance

✔️ Avoid errors, ensure quality

Reduce production errors through precise material identification directly on the processing line.

✔️ Increase productivity

Optimize your processes with fast in-line analyses and accelerated workflows.

✔️ Reduce costs

Avoid expensive rework and rejects – recognize potential mix-ups at an early stage and act proactively.

Increase efficiency and quality – with next-generation laser technology

Take advantage of our smart mix-up check and make your production safer, faster and more economical.

Where measurement technology becomes reality

Visit us in downtown Aachen

Visit us at our location in Aachen. We will be happy to advise you on our products, services and solutions.

Find us

Gewerbepark Brand 78

52078 Aachen